This is The Engineering Heritage Skills Initiative blog about the project's activities in the North East of England.

Scroll down for the latest North East EHSI

news

The EHSI Project will close on Tuesday 31st of March 2015

North East Placement Providers

The EHSI project in the North East is very grateful for the vital role played by our placement providers who have agreed to put their time and effort into supporting an EHSI trainee during a one year traineeship. Without them simply wouldn't have been an EHSI project.

.

Stephen Hopper was working on conservation and restoration projects at the museum. He has now graduated from the project and is working in an engineering role at South Tynedale Railway in Alston.

North East Maritime Trust - two traineeshipsRosie Power and Phil Smith are working part time at NEMT on heritage boat building and repair. Their traineeships are the equivalent of a one year traineeship spread over a two year period, they are both coming towards the end of their the second year of their part-time placement at the NEMT's South Shields boatyard. They completed their traineeships at the end of February and are both currently seeking employment.

South Tynedale Railway - One traineeship -

Zach Taylor has an engineering background and was working on engineering projects at Alston. Zach graduated from the project at the end of January 2015 and is currently seeking employment.

Zach Taylor has an engineering background and was working on engineering projects at Alston. Zach graduated from the project at the end of January 2015 and is currently seeking employment.

Stephenson Railway Museum - North Shields and NEMT South Shields

Joe Power has a woodworking background is working on conservation and restoration projects at SRM four days a week and works one day a week on boat building at NEMT. He graduated from the project at the end of January and is currently seeking employment.

Tanfield Railway - Marley Hill - one traineeship

Michael McCann started his placement at Tanfield Railway working mainly on the Restoration of locomotive 'Horden'. Later in the year Michael's placement was changed to a combination of NELSAM and Locomotion. Michael graduated from the project at the end of January and is currently working for an industrial machinery installation company.

HMS Trincomalee, Hartlepool - one trainee - New traineeship for 2014-15

Ryan Auton is our trainee at a new placement at HMS Trincomalee where he will be working on keeping the ship in good repair. He has been taken on by the HMS Trincomalee Trust as a ship maintenance hand.

William Lane Foundry Middlesbrough - New traineeship for 2014-15

We have recruited two trainees, Joel Vernon and Ryann Hodgson for another new placement at William Lane Foundry in Middlesbrough. William Lane have been kind enough in the past to host trainee visits to see the casting process, but now are providing placements in traditional sand casting techniques at the foundry. Joel and Ryann graduated from the project at the end of February 2015 and are both currently seeking employment.

Stanegate Restoration and Replicas - Haltwhistle - one traineeship

Stanegate have provided their fourth and last traineeship for Jamie Cowens, who this year has mainly been working on the company's contract to repair a former Peterhead Prison Railway Coach. Jamie will be the final trainee to graduate from EHSI when he leaves the project in early on the 9th of March 2015. Its most likely that he will then take up a role in the building trade.

NORTH EAST EHSI LATEST POSTING

After a long gap in postings due to a very busy December and January here's an update to the North East blog.

We have recently said goodbye to the majority of our Yorkshire and North East trainees who graduated from the project at our graduation ceremony at the Preston collection in Hutton Rudby in North Yorkshire on the 21st of January.

Through the generosity of the Preston family we were permitted to use the excellent facilities at the collection, to celebrate the achievements of the project, its trainees and our supportive placement providers. Without the support of our placement providers the project would simply not have been possible.

Here's a shot of the 14 graduates on the stage at the Preston collection with the collection's huge Gavioli organ in the background.

Left to right they are:-

Ryan Auton - HMS Trincomalee - Hartlepool

Jamie Cowens - Stanegate Restoration and Replicas - Haltwhistle

Zach Taylor - South Tynedale Railway - Alston

Dominic Wright - Rusty Bug Workshop - Skelton Cleveland

Phil Smith - NE Maritime Trust - South Shields

Joel Vernon - William Lane Foundry- Middlesbrough

Steven Hopper - Locomotion - Shildon

Peter Standring - Kirklees Light Railway - Clayton West Nr. Huddersfield.

Ryann Hodgson - William Lane Foundry- Middlesbrough

Rosie Power - NE Maritime Trust - South Shields

Joe Power - Stephenson Railway Museum N. Shields and NE Maritime Trust - S. Shields

Josh Smith - North Yorkshire Moors Railway

Josh Smith - North Yorkshire Moors Railway

Callum Darraugh - North Bay Railway - Scarborough

Jamie Godwin - Adam Dalgleish Engineering - boilermakers - Stockton-on-Tees

Another update from the North East, this time it concerns Ryan Auton our EHSI trainee at HMS Trincomalee in Hartlepool.

Ryan has been doing a variety of work on the ship recently.

Lets look at some deck caulking repairs that Ryan did earlier in the autumn when the weather was a lot better.

First the tools and materials. Ryan kindly laid these out on a table below decks to give readers an idea of what's involved. The caulking material is oakum, which is strands of hemp fibre which has been soaked in Stockholm Tar. The oakum is twisted into a rope and hammered into the gaps between the deck planks, once any rotted or water laden caulking has been removed. As the shots below show caulking irons come in various sizes depending on the depth of the caulking and the gaps between the planking.

All that careful work is then sealed against water ingress by with hot tar.

These two shots how some caulking on the top deck and a more complex job in and around one of the capstans, where water can become trapped. In this case quite a bit of rotten caulking was removed due to rain water penetration.

One morning in the autumn a broken shackle was discovered which secures the gaff, part of the rigging on the aft mast, from which the Royal Navy Ensign is flown.

The shackle snapped and although the considerable weight of the gaff was taken by other parts of the rigging it was important the shackle was replaced before the ship was opened to the public. Here's a close up of the snapped stainless shackle with shows signs of a possible brittle fracture.

Here's a shot of the aft mast.

This shot shows the gaff running at an angle left to right across the shot.

The snapped shackle was holding up the chain in the middle of the shot which in turn was supporting the gaff from the aft mast.

The captain's cabin, which is used for functions such as weddings, was also recently re-painted, Ryan's job was to paint the lower green section. Here's a panoramic shot of the captain's cabin after the repaint.

Ryan's next job will be dealing with the removal of some rotted inner hull planking near one of the cannons on the gun deck,

This shot shows that some of the inner planking has been removed to inspect the space between the inner and outer hull planking. No real signs of rot so far but..............

Get a little closer and the planking shows the need for some new timbers.

Earliere this week I visited EHSI trainee, Joe Power at The North East Maritime Trust in South Shields.

Joe works at two placements, one day

a week at NE Maritime Trust (NEMT) and four days at Stephenson Railway Museum (SRM).

We've seen Joe at SRM before in blog postings; I thought it would be

interesting to see what he gets up to at NEMT.

Joe has been helping out making a new piece of stringer for

the port side of the hull of lifeboat Henry Fredrick Swan. The piece of oak that Joe has been shaping to replace a

piece of rotted wood has virtually no straight lines in it, so it’s quite a fiddly

job. In this shot Joe offers up the piece of replacement stringer

to the hull to test the fit.

In this shot Joe holds the

piece of oak away from the hull so the shape of the piece is easier to see.

Joe shows me a piece of

African iroko hardwood, which Joe will use the make a new NEMT trust sign, which

will be fitted to the boatshed's gable, to replace the original shown below, which has

deteriorated in the wind and weather.

As well as working on the

lifeboat, Joe has been helping out on the rebuilding of a Tyne foy boat. As this shot shows, this

vessel is having much of its hull and planking replaced.

Here’s a shot from the stern

of the foy boat, which has already been repaired, note the two sighting posts

that have been fixed to the stem and stern as reference points, to ensure the hull remains straight

when it’s being rebuilt.

Back at SRM, Joe has fitted a

new drawbar and hook to the museum’s Peckett locomotive. This was following attention

by contractors, who built up the hole in the buffer beam that houses the

drawbar, to correct wear and bring it back to its original size. Here’s a close

up of the hook and the refurbished hole in the buffer beam in which it now fits.

On the floor of the workshop

lies a volute spring, that will be fitted to the draw hook this week. The

spring puts the drawbar under tension and helps to smooth out the drawbar

forces as the locomotive accelerates and decelerates the train.

Posting for the North East 20.10.2014

Last week, all EHSI trainees attended a blacksmithing master class at Adrian Wood's forge at Hornby in North Yorkshire. On Thursday 16th and Friday 17th it was the was the turn of the North East trainees and some from the Yorkshire group to get some experience at the anvil.

Here's a group shot at the start of the two day session.

Here's a close up of two of the handles.

Posting for the North East 09.10.2014

Last week, all EHSI trainees attended a blacksmithing master class at Adrian Wood's forge at Hornby in North Yorkshire. On Thursday 16th and Friday 17th it was the was the turn of the North East trainees and some from the Yorkshire group to get some experience at the anvil.

Here's a group shot at the start of the two day session.

Left to right Ryan Auton HMS T, Joe Power SRM/NEMT, Michael McCann Locomotion NELSAM, Jamie Godwin ADE, Ryann Hodgson and Joel Vernon W Lane, Zach Taylor STR, Jamie Cowens Stanegate, Steven Hopper Locomotion and John Stelling EHSI Gang Leader.

Later in the session we see the interior of the building with trainees in action at a number of forges, working on their various projects.

Lets now look at individual projects. Carrying on from the first session on the 14th and 15th Phil Smith and Rosie Power worked voluntarily for the North East Maritime Trust on the ironwork and pintle shaft of the rudder of the 'Henry Fredrick Swan' lifeboat.

In this shot Phil holds the work piece with a piece of tube inserted between the two sides of the strap, whilst Rosie operates the fly press, to flatten the strap, to make both sides parallel and thus a good fit on the rudder.

In this shot Phil Smith looks at the parallel straps that he has made to replace the rusted ironwork on the original rudder. After heating the ends of the straps were cropped so that they wouldn't foul the pintle shaft when fitted to the hull.

After cropping, Phil slowly cools one of the work pieces.

After cropping, here's the two finished work rudder straps.

Later, the straps are test fitted in place, on the old rudder, to check for fit.

During the two day session, Adrian Wood kindly welded up a new pintle shaft for the rudder, using part of the old shaft, which was welded to new material brought by Phil, from the NEMT.

After Adrian had butt welded the pintle shaft, Phil dresses the weld with an angle grinder.

The work done by Rosie and Phil, supported by Adrian Wood, has made a very useful contribution to the restoration of Henry Fredrick Swan's, rudder assembly.

Jamie Cowens from Stanegate Restoration decided to make a carriage key by forging. Due to the small size of the job these keys would normally be hand filed to shape but Jamie thought he'd tackle the job by forging.

In this shot we see Lee Webber showing Jamie the technique he needs to use to forge the handle of the carriage key.

Here's a shot of the handle after Jamie has punched a hole in the handle.

After he's made the shaft of the key he tries the fit of the shaft on the handle.

Here's a shot of the components of the key, on the anvil, after cooling.

Later the shaft is riveted to the handle, after localised heating with an oxy/propane torch.

Jamie Godwin decided to make a pair of tongs, to use when he's hot riveting at his placement at Adam Dalgleish Engineering in Stockton.

In this shot he is starting to made one of the tongs.

Adrian gives Jamie advice about forging the tongs.

Work in progress, here are the two tongs cooling beside the anvil.

In this shot Jamie starts to thin out the handle of the tongs, in blacksmith trade, these are called 'reins'.

Joe Power who has placements at Stephenson Railway Museum four days a week and one day at the North East Maritime Trust decided to make a large and small Roubo workbench clamp.

These clamps are pushed into a circular hole in a workbench and they rely on the friction of the shaft in the hole and the springyness of the steel from which they are made. The tool is named after an 18th century French carpenter and cabinet maker Andre Jacob Roubo, who developed a design for a joiners workbench, that incorporated this simple but very effective design of clamp.

In this shot Joe starts roughing out the small clamp.

After a good deal of work the small clamp is finished.

As the large clamp needs bit more work to shape the blank to the right size, Adrian helps out with the pneumatic hammer, which makes short work of the job.

Later Joe works on the larger Roubo clamp, as the photograph shows this is a much more substantial clamp.

Little and large, There's two days work in this photographs, but the symmetry between the two clamps is, I think impressive.

John Stelling also took part in some forging, making a rake for his army field kitchen.

Michael McCann whose has placement is currently shared between at NELSAM and Locomotion in Shildon decided to make a chipping hammer.

He used tool steel to make the hammer head, which he planned to mount on a twisted wire handle in the traditional blacksmith's style.

In this first shot we see him beginning to shape the head of the chipping hammer.

In this shot he uses a wire brush to clean scale from the work piece.

Here's the finished head.

Ryan Auton from HMS Trincomalee decided to make a caulking tool for working on the decks of the ship.

In this shot, he's widening the blade of the tool steel work piece.

Later, with John Stelling's help, the fly press is used to make the indentations in the shaft of the tool, which Ryann planned to fit with a blacksmith style wire handle, to keep his fingers out of harms way when caulking the decks.

Steven Hopper from Locomotion made a fireside companion set for the wood burning stove at home.

In this shot he's turning over the ends of one of the work pieces to make a handle.

later in the day we see him forging the business end of the rake.

Joel Vernon and Ryann Hodgson from William Lane foundry decided to make some very small foundry trowels, which they planned to use to smooth out the sand when making moulds using complex patterns.

Here's a shot of them sharing the same anvil shaping the trowel handles.

In this shot Joel uses an angle grinder to clean up his trowel.

Here we see Ryann drilling the holes for the rivets which will hold the blade to the handle.

Here's the finished trowels. Joel used a piece of decorative scrap for his handle, which explains the finish in top photo. Ryann planned to finish off his trowel at work and fit the sharp tang with a more comfortable wooden handle.

Zach Taylor from South Tynedale Railway helped out John Stelling, by making a tie down handle for one of NELSAM's military vehicles.

In this shot he's upsetting the end of a work piece to create the ends of the handle, which he will eventually pierce to make the holes, through which, the bolts, fixing the handle to the vehicle chassis, will pass.

in this Shot Lee Webber shows Zach how to pierce the work piece.

In this shot Zach uses a sharp punch to start the process of making a hole in the work piece.

In this shot we see one end done and one to go.

Later Zach planned to bend the work piece to this full size pattern, which he drew out on a piece of plywood.

Posting for the North East 09.10.2014

I visited the North East Maritime Trust in South Shields earlier this week and was able the work that EHSI trainees, Rosie Power and Phil Smith.

Lets look at progress on on lifeboat Henry Fredrick Swan, the big project the trust's volunteers have been working on, for the past few years.

Volunteers are getting on with the huge task of caulking the hull to make it watertight, when its eventually launched. Here's a close up shot of an area of caulked hull planking.

The hull sports a coat of primer and the scaffolding is up, to allow access to the top of the stern and the whaleback which is mounted on the stern.

Looking inside the stern, work continues on completing the fitting of the whaleback to the hull.

Rosie and Phil have now turned their attention, to the repair of a foy boat that the trust is currently rebuilding.

Here's an overall shot of the Foy boat. As can be seen it needs substantial work to make it usable once more.

These boats were used to handle the mooring lines of larger vessels. The name Foy is associated with the rivers of the North East of England.

Phil and Rosie are currently working on replacing the apron, which has snapped at some time and needs replacement This is a piece of timber, that connects the keel to the stem in the bow of the boat. In this shot, Phil Smith has placed the old apron in the position the new timber will be in when fitted to the hull.

Here's a shot of the old apron sitting on a block of oak, which will later, be cut to size and shaped, to become the new apron.

In this shot Phil holds in place the piece of timber, which will eventually become the stem, in the bow of the boat.

Whilst Phil was showing me the foy boat, Rosie was working on a wooden holder, which will be used to carry personal protective equipment such as ear defenders and goggles, around the boatyard.

Later Phil and Rosie launched salmon boat ' Spring Tide'.

They were providing a ferry service, for trust members who needed to cross the Tyne, to assist Peter Weightman with moving, 1936 built fishing boat 'Sovereign' In the move to the trust's neighboring boatyard, owned by boat builder Fred Trowell, for repairs. 'Sovereign' will be towed by another of the Northumbrian Fishing Heritage Trust's boat's, 1947 built Rachel Douglas.

In this shot Rosie waits for Phil to lower the trailer down the slipway with his van.

Phil sculls Spring Tide, to moor and fit the outboard engine.

Engine fitted and ready to go.

The following day I crossed under the Tyne to visit Joe Power at the Stephenson Railway Museum.

No photos I'm afraid, but whilst I was there, I looked at the display in the museum created by the N Tyneside Steam Railway Association, covering the history of the railways in the local area.

Click on these links to see more about the colliery railways and associated shipping activity, that at one time, dominated this area of what is now North Tyneside.

https://ww.historypin.org/map/#!/geo:55.016608,-1.497544/zoom:11/

To use the History Pin website type the postcode into the search function NE29 8DX

To use the History Pin website type the postcode into the search function NE29 8DX

Posting for the North East 18.09.2014

Yesterday I was in NELSAM, where I took the opportunity of taking some photos of Ryan Auton who is working away from his normal placement at HMS Trincomalee in Hartlepool.

Ryan needed to carry out some work, not available at HMS T, to enable him to gather evidence to submit for his NVQ. The particular job was the repair of the framework of a Blackpool tram, now housed in a new shed at NELSAM to house the collection of the North East Traction Trust.

The Blackpool 'Hovertram' No.735 had been involved in a collision, which had damaged the wooden framework of the tram's bodywork.

Read more about NETT at http://www.neett.co.uk/

In this shot we see Ryan testing the fit of a piece of timber which will become one of the uprights in the trams rear entrance doorway.

Posting for the North East 16.09.2014

Yesterday I was in NELSAM, where I took the opportunity of taking some photos of Ryan Auton who is working away from his normal placement at HMS Trincomalee in Hartlepool.

Ryan needed to carry out some work, not available at HMS T, to enable him to gather evidence to submit for his NVQ. The particular job was the repair of the framework of a Blackpool tram, now housed in a new shed at NELSAM to house the collection of the North East Traction Trust.

The Blackpool 'Hovertram' No.735 had been involved in a collision, which had damaged the wooden framework of the tram's bodywork.

Read more about NETT at http://www.neett.co.uk/

In this shot we see Ryan testing the fit of a piece of timber which will become one of the uprights in the trams rear entrance doorway.

Here's a wider shot of the tram.

Both sides of the door needed repair, here's a close up shot of the left hand side, where you can clearly see the replacement framework, installed by Ryan.

Damage on the left hand side was less serious.

Looking at the bottom of the left hand side of the doorway, Ryan also had to scarf in new wood to replace an area shattered in the collision.

Looking inside the doorway, there are mounting brackets that connect the wooden framework to the tram's underframe. I'll keep an eye on progress and post more shots as the job moves towards completion.

I was also in Haltwhistle where at Stanegate Restoration they are making solid progress on the Peterhead Prison Railway coach, using the description coach, loosely!

In this shot you can clearly see the problem the team at Haltwhistle have been faced with. The coach body, like many, was 'grounded' at a local farm after the prison railway closed.

So the wooden structure rotted from the ground upwards.

This meant that the new wood had to be scarf jointed into place, on all 16 upright structural members to replace the rotted wood. The coach body will eventually be painted a grey finish, which it is hoped will help to disguise, the large amount of new wood that has had to be inserted in the structure

The pitch pine structure that was above the ground is undamaged, apart from locations where bolts that pass through the wooden structure and have rusted, causing the fixings to 'burst' and damage the wood. Again this is a common problem that Stanegate have to face, when rebuilding 'grounded', railway vehicle bodies.

This shot below shows the next steps Stanegate are taking to install the floor of the coach.

The Structure of the prison coach is very unusual.

The bottom of the right angle bracket in this shot will be level with floor boards. Below this will be fixed, a perimeter floor support beam, which will be notched to fit between the uprights, ending level with the exterior of the uprights.

There will be then conventional cross beams to carry the floor, with the wall planking fixed to the inside face of the uprights.

What's most unusual, is the the coach uprights will then hang outside the underframe below the top of the underframe. The body will not just rest on top of the underframe, and be bolted in place, as is the usual practice. Notice a couple of the window bars which await fitting.

I mentioned bolts. Stanegate are keen to keep the coach's appearance as a true to the original design as possible. All the original bolts that hold the coach were one off blacksmith made items. The vast majority have rusted through during the coach's time on a farm.

Stanegate have recovered all the heads of all the rusted bolts and have matched them with suitable lengths of studding. The heads will then be welded to the lengths of studding which when installed in the framework and painted should look very much like the originals.

In these two shots Stanegate trainee Jamie Cowens grinds a bolt head and then examines it to ensure its suitable shaped for welding.

Here's a selection of the team's work ready for welding.

Elsewhere in the workshop, the corrugated iron roof has been painted, ready for fitting when the time comes.

Yesterday I visited Tanfield Railway, here are some shots of the work that our EHSI trainee Michael McCann has been involved with.

In this first shot we see the buffer beam that Michael was working on in an earlier post, is now in the process of being fitted to the locomotive's frame.

In this first shot we see the buffer beam that Michael was working on in an earlier post, is now in the process of being fitted to the locomotive's frame.

In this shot Michael and volunteer Brian High are removing a stubborn fitted bolt.

In an earlier post we saw Michael using a Rotabroach tool to

cut the hole in the buffer beam for the draw hook, this now, just requires the

removal of a small amount of material, to bring it to a finished size.

Posting for the North East 15.09.2014

I happened to visit Locomotion on Saturday the 13th and took these shots of the restoration work being carried out on former GWR pannier tank No.5775, which appeared in the 1970 film 'The Railway Children'. The locomotive is now getting its top coats applied and very smart it looks too.

Posting for the North East 12.09.2014

Aircraft don't feature too much in our pages. Here's a couple of shots of the fuselage of 1965 built Trident 1C G-ARPO which is preserved at NELSAM by the Save the Trident Group. In this first shot Michael McCann dips the roller in the paint prior to handing it up to Tony Jarrett who is applying the second coat of yellow paint to the upper part of the fuselage.

Posting for the North East 02.09.2014

I happened to visit Locomotion on Saturday the 13th and took these shots of the restoration work being carried out on former GWR pannier tank No.5775, which appeared in the 1970 film 'The Railway Children'. The locomotive is now getting its top coats applied and very smart it looks too.

Earlier today I was at Tanfield Railway

Michael McCann was working with Brian High on the buffer beam of Andrew Barclay Locomotive 'Horden'. Here's a shot of them working on removing a very tight fitted bolt from the buffer beam.Posting for the North East 12.09.2014

Aircraft don't feature too much in our pages. Here's a couple of shots of the fuselage of 1965 built Trident 1C G-ARPO which is preserved at NELSAM by the Save the Trident Group. In this first shot Michael McCann dips the roller in the paint prior to handing it up to Tony Jarrett who is applying the second coat of yellow paint to the upper part of the fuselage.

Next move is for Tony to apply the paint, there's quite a bit to do! The plan is to paint the aeroplane in the distinctive 1970's colours of Northeast Airlines. The tailplane, wings and engine nacelles were removed when the aircraft was moved by road from Teeside Airport. The group plan to re-assemble the aircraft over time.

Get the full story at

Here's a shot from 'Save the Trident' website, showing the partially completed paint job.

Going north across the Tyne, at Stephenson Railway Museum, Jo Power is in attendance, when the boiler of Peckett locomotive, Jackie Milburn has its hydraulic test, after repairs to its boiler.Under the watchful eye of the boiler inspector, boilers are often tested hydraulically to one and half times their steam working pressure.In this shot Joe uses an inspection light to see if there are any leaks, .

Joe continues his observations in the cab looking for leaks from the boiler fittings. The hydraulic test was successful and the engine now moves on to the next step, the steam test.

With the museum's permission, Joe has made a special jig in which to mount wood, which will be made into arrow shafts. The work pieces are planed by hand from oblong to round by inching the work piece step by step until a round shape is created. In this shot Joe marks out the jog to create the hollow which will hold the wood from which the arrow shaft is made.

Joe starts cutting the groove in the jig,which will hold the wood fro the arrow shaft.

Here's a shot of a work piece in the jig.

This end on shot shows it will require a lot of finishing to get from oblong to round!

For comparison here's a finished arrow with its head fitted sitting in the jig.

At the North East Maritime Trust in South Shields, Rosie Power and Phil Smith are working on the port side of the 1917 built, Henry Fredrick Swan lifeboat. Work is now focusing on the port side of the hull to solve the problems of plank splitting caused by corrosion of hull fixings combined with the need to repair the port stringer. In this shot Phil checks a piece of the old stringer that has been removed. This will be used a s a template for a new piece of stringer which will be scarf jointed back into the hull.

At the site where the new section of stringer will be fitted, Rosie works on the stringer.

Rosie works on the stringer, shot from the outside of the hull. The repair is complicated, by the fact the the stringer, runs horizontally across this section of damaged hull planking.

Later Phil takes a piece of hardboard to make a template, for a new diagonal plank that will be cut to the size of the template.

Having cut a template for a plank, he checks the fit on the hull.

Today I visited Locomotion, where I took some shots of the progress the team is making on the GWR pannier tank, that is being repainted in the livery it carried in the 1970 film 'The Railway Children' This shot shows the upper part of the locomotive, which after receiving its undercoats, has now had its first top coat of gloss applied.

Elsewhere on the locomotive, the task of rubbing down the undercoats before applying the first top coat continues Four of the museum's volunteer team are at work, with random orbital sanders and sandpaper.

Inside the cab, work has started on cleaning up the copper pipe fittings.

Later in the day, after working on his NVQ paperwork with John Stelling, Steven Hopper was back working on the GWR pannier tank.

Michael McCann was working at Locomotion today. He has welded up new brackets, to support new wheels, that will be fitted to the museum's movable fences on the outside concrete apron. When moved in position the fences segregate the museum's footpaths, from the railway lines, during shunting operations.

In this workshop shot Michael and the museum's Richard Pearson, check the fit of the wheels on the bracket.

Here's a close up shot of the bracket.

Outside the museum, here's a shot of the old castors, the new stronger bracket is replacing.

After supporting the movable fence with the fork lift, old bolts are removed from the fence to fit the new wheels.

After drilling new mounting holes the gate's weight is supported by the fork lift and the new bracket test fitted. A solid job.

Posting for the North East 01.09.2014

Welcome to our first autumn posting. On Saturday the 30th of August I visited the North East Maritime Trust, to see EHSI trainees Rosie Power and Phil Smith.

For months now, they have been working on the stern whaleback, however, work on the whaleback is nearing completion. In this shot we see NEMT treasurer Tim West, working in the stern of the 1917 lifeboat Henry Fredrick Swan, with the daylight shining through the gaps between the top of the hull and the bottom of the whaleback. Fitting the whaleback will need great care and attention to detail.

Looking from the outside at the top of this shot can be seen the sharply curved planks on the whaleback, that took such a lot of time to rebuild in the past months. A solid block of wood will be shaped to fill the gap between the top of the rudder post and the whaleback. Since we last saw it, the hull has also had a coat of primer and the process of caulking the planking has started.

In earlier post we saw Phil Smith working on the repair of the centreboard, a retractable keel which pivots in a slot on the hull. The centreboard is used to provide a counter to the lateral force of the sails.This shot shows the metal housing in to which the centreboard retracts when not in use, this has now been permanently installed in the hull .

Phil and Rosie have now moved back to working on the lifeboat's hull. The current job is to repair around a dozen locations on hull where metal bolts and fixings that pass through the hull have become corroded. This corrosion has sometimes split both layers of the hull's diagonal planking and occasionally damaged the framing.

In this shot Phil marks the inside layers of planks that will need to be removed to repair one of the damaged areas.

Here's a close up of the markings, you can also see the many copper nails, that hold the planks in place.

Outside, Rosie marks the exterior planking that needs to be removed.

Due to the overlapping double diagonal construction, a small amount of damage means removing quite a few external internal and external planks. The strong, diagonal construction, means that the frames, one of which is vertical in this shot, can be of relatively light construction.

Posting for the North East 20.08.2014

Both myself and John Stelling visited Zach Taylor at South Tynedale Railway during August, lets see what he's been getting up to in the railway's Alston workshops.

The railway have given permission to Zach, to use the workshop machinery, to machine the castings of a Stuart No.9 horizontal mill engine, he is building. In this shot, he consults the No.9 manual, before setting the cylinder up in the vertical miller.

In this shot he's boring the cylinder, in the vertical milling machine, having set it up on a vertical angle plate with a dial gauge.

Later, he faces off a cylinder cover casting in the lathe.

Later in the month, Zach was investigating a fuel flow issue, on one of the Hunslet mines locomotives. He's had to drain coolant from the engine, remove the radiator, shown in this shot and its associated cooling hoses.

Zach explained to me, the complex system of pipes that make up the locomotives fuel system. Fuel is fed from the fuel tank above the transmission, to the fuel pump, the fuel filter, injectors and return pipework to the tank.There's something in all that pipework, that causing fuel starvation. Fault finding can be a long tedious job! The cylinder heads, which Zach was repairing in a previous posting, have now been refitted.

Zach showed me the work he'd been involved with in rebuilding the clutch on another of the Hunslet diesels the railway owns.

A general shot of the clutch is shown below.

Left to right - The clutch stop which stops the clutch rotating during semi-automatic gear changes, the coupling connecting the output from the clutch to the gearbox, the clutch release bearing and operating rod to the cab, the multiplate clutch and finally the engine flywheel, with the recently installed electric starter motor, far right.

This clutch assembly was built up from components from a number of locomotives, including a donor chassis, from which the railway can take, hard to find parts. Zach machined the clutch release bearing, during the re-assembly of the clutch.

The release bearing, which Zach machined, is right in the centre of this shot.

Zach has also been involved in the steam fleet, having assisted with the re-assembly of 1918 built, Henschel locomotive, Thomas Edmondson. Reassembly followed repairs to its axleboxes. Here's a shot of the locomotives Walschaert's valve gear and driving wheels.

Zach also explained that the injector body, shown in the shot below, was also repaired recently.

I recently visited Tanfield Railway where EHSI trainee Michael McCann was working with, volunteer Brian High, on 1904 built Andrew Barclay 'Horden' In the shot below Brian is explaining to Michael, the recent job he did on the new front tubeplate for Horden's boiler. He explained, that he used a specially made narrow cutting tool, to gradually cut a hole in the tubeplate for the main steam pipe, the pipe will take steam from the regulator, to the steam pipes for the locomotive's two cylinders.

Here's a close-up of the hole for the steam pipe and the blank that was removed, during a very careful machining operation.

On the day of my visit Michael, was using the magnetic drill to rough out the rectangular holes in the new front buffer beam for Horden. The roughing out was being done with a Rotabroach cutter. Here's a close up of the business end.

Rotabroaches come in different sizes. They save quite a bit of time. The alternative would be to chain drill out a blank which would take a lot longer to complete

However, there is still some chain drilling to do and in this shot Michael uses the magnetic drill, with green cutting paste, to remove some more steel, from the hole for the drawbar.

Later, he takes a more basic approach and removes more material with cold chisel.

Here's a close up of the hole for the drawbar. As much material as possible will be removed with the magnetic drill. It's planned that the hole will be finished to its final dimensions, with an air driven, rotary burr.

Another job for later, will be to remake these plates, which bolt to the front of the buffer beam and protect the machined hole in the buffer beam from wear, by absorbing the buffing shocks from the drawbar.

Posting for the North East 06.08.2014

On Monday the 4th of August I visited Ryan Auton EHSI trainee at HMS Trincomalee in Hartlepool. In earlier posts we had seen Ryan making repairs to the ships bulwarks. At that time it was work in progress, so I thought readers might like to see how the repairs turned out.

Here's a reminder of how the repairs are done. In the shot below we can see a section of decorative moulding where water got behind the moulding and caused it to rot. Ryan cut out the rotted wood back to good material. He then made a new piece of hardwood moulding. Behind the wooden plugs that are yet to be painted, are recessed holes through which coach bolts are screwed into holes drilled into the body of the bulwark.

In this shot you can the painted repair that was featured in an earlier posting. As can be seen its a very neat repair with the head of the plug smoothed off, and under the plug is silicone sealant, to deter the entry of any rainwater.

Repainting the hull has been the big summertime job this year. The HMS T team are using a new water based paint system, that has shown promising results on the port, left hand side, of the ship. In this shot Ryan checks the paint finish under the chain plates. The shot gives a good idea of scale and the sheer size of the task of repainting this 1065 ton, 150 foot long and 39 foot beam, hull.

Here's a close up.

Work has now moved to the starboard, right hand side, of the ship.

The work is carried out from a floating pontoon, In this shot Ryan is applying paint with a roller, to the underside the the chain plates.

Again a further away shot gives an idea of scale. Imagine manually handling that anchor in a rough sea!

The team also recently repainted the ships 'busthead'. In this shot Ryan shows the cramped position available for some of the work. The remainder of the work was done from a floating pontoon, where access is a lot easier.

Here's a close up of the busthead which reflects the ships Indian origins.

Postings for the North East 31.07.2014

Locomotion

Unexpectedly, I was in Locomotion again yesterday, so here's another update showing how the restoration of GWR pannier tank 5775 is going.

Since last week one of the pannier tanks has had its first coat of primer.

In this shot we see Steven Hopper putting the second coat of undercoat on a driving wheel.

Behind him you can see that the sandbox has already had its first top coat applied.

This close up of the smokebox door, shows how much hard work goes into getting down to bare metal, before primer is applied.

To ensure that the appearance of the locomotive is re-created as it appeared in the film, the workshop notice board shows photographs and stills form the film, to ensure the correct final finish is achieved.

NELSAM

Getting back to the MK's clutch change, here's a shot of the clutch and pressure plate s after they were removed from the machine. The clutch plate was down to the rivets in places and the pressure plate shows scoring that is a issue that will have to be resolved.

Postings for the North East 25.07.2014

Michael McCann is working two days a week at Locomotion in Shildon with fellow EHSI trainee Steven Hopper. The project to repaint a former GWR pannier tank, last featured on a posting on the 7th of July. There's been quite a bit of progress since then, with the chassis and wheels now undercoated and the locomotive's structure above the running plate, largely rubbed down.

Here are three shots of the locomotive front, back and one side.

Michael McCann is working two days a week at Locomotion in Shildon with fellow EHSI trainee Steven Hopper. The project to repaint a former GWR pannier tank, last featured on a posting on the 7th of July. There's been quite a bit of progress since then, with the chassis and wheels now undercoated and the locomotive's structure above the running plate, largely rubbed down.

Here are three shots of the locomotive front, back and one side.

Rubbing down the paintwork has revealed some of the GN&SR, Great North and South Railway, lettering that the engine carried on its pannier tanks for the Railway Children film.

The film, released in 1970, was made on the locomotive owner's line, the Keighley and Worth Valley Railway. The locomotive was withdrawn for service some time ago and has been on display at the KWVR. To celebrate the 45th anniversary of the release of the film, Locomotion are repainting the engine in the GN&SR livery, it carried during the film.

As the pictures show there's plenty of rubbing down to do, here's a shot of Michael using air driven, orbital sander, preparing the front of the cab for its undercoat.

Whilst Michael was working on the cab Steven was getting on with rubbing down the undercoat already applied to the locomotives frames.

Here's another shot of the wheel and frame, which have been needle gunned and now undercoated.

Later, it came time to remove the steam coil that feeds the locomotives hydrostatic lubricator.

Here we see Locomotion volunteer Trevor Addison and Steven Hopper, undoing the joints on the pipework prior to removing the coil from the locomotive.

Here's the coil, along with the condensate it contained, in the workshop wheelbarrow.

Here's a shot of the footplate which Trevor has been working on cleaning up.

This close-up shows how much cleaning up will be needed, prior to any paint being applied to the roof area of the cab.

5775 was built in 1926, but fitted to the cab side doors, is this very useful advice issued, by the GWR in January 1909!

Postings for the North East 22.07.2014

EHSI trainee Michael McCann has been working at NELSAM recently helping out on job to change the clutch on an ex-army Bedford MK truck, the 4 wheel dive military version of the civilian Bedford TK. The MK was produced by Bedford and later AWD for 33 years from 1959 to 1992.

Here's a few shots of the vehicle just before the gearbox was removed.

Here's an overall view of the 4 tonne truck, with jacks lined up ready for work.

The lower section of the bell housing has been removed showing the clutch cover and the flywheel.

This is a shot of the four speed main gearbox which has to be removed to change the clutch.

Work got started earlier today to remove the gearbox, the first step was to remove the gear selector from the top of the gearbox.

Next step is to take the weight of the gearbox on a trolley jack and using slings around the gearbox.

After the weight is taken the bolts connecting the gearbox to the bell housing are removed. In this shot, the gearbox has been disconnected and is being lowered by Michael and John, to ground level, on the scissors trolley jack. It would be a lot easier with a pit says John!

The gearbox is manhandled from under the truck.

The gearbox is put to one side whilst the team get started on the removal of the clutch.

Postings for the North East 08.07.2014

At Locomotion they are repainting the GWR Pannier tank which once starred in the 1970 film the Railway Children as being owned by the mythical 'Great Northern and Southern Railway. Obviously someone at Locomotion has converted the locomotive to LNER ownership whilst in the North East!

44 years ago the locomotive carried, an unusual to say the least, brown livery, similar to the test paint on the front of the pannier tanks in this shot.

Research is being carried out to ensure the right shade of brown is used, when the vast amount of preparation is complete and undercoating starts.

In this shot we see on the left, Steven Hopper the EHSI trainee at Locomotion.

John also popped in to the North East Maritime Trust to see Rosie Power and Phil Smith.

Here's a shot of them both, under the whaleback that they have been working on for ages, which has now been offered up to the stern of the Henry Frederick Swan Lifeboat.

John on his travels, has also visited Ryan Auton at HMS Trincomalee in Hartlepool. These first couple of shots show his navigation skills, as he moves a work pontoon across the dock and loads it with wood for repairs on the ship.

Later Ryan had a simple repair to an access gangway to do. Here he removes the panel that covers the gap between the end of the gangway and the side of the ship.

John Stelling recently visited Joe Power at Stephenson Railway Museum who is building a portable forge, lets see how he's been getting on.

Joe gets on with cutting steel to make the legs of his forge.

Postings for the North East 27.05.2014

Moving south form Haltwhistle I have some shots from earlier in June, of EHSI trainee at the South Tynedale Railway, Zach Taylor. Readers will recall that last year's trainee, Andrew McIntyre repaired Hunslet mines locomotive 'Cumbria's' transmission. The Gardiner engine however, is beginning to show signs of engine wear and the railway has decided to strip it down to investigate. The shots that follow show Zach removing the inlet and exhaust manifolds and the cylinder heads. Eventually the Connecting rods and pistons will also be removed to check the state of the piston rings and cylinder bores.

Here we see Zach at the start of the job, the bonnet and cab have been removed and he's starting to remove the manifolds.

At Locomotion they are repainting the GWR Pannier tank which once starred in the 1970 film the Railway Children as being owned by the mythical 'Great Northern and Southern Railway. Obviously someone at Locomotion has converted the locomotive to LNER ownership whilst in the North East!

44 years ago the locomotive carried, an unusual to say the least, brown livery, similar to the test paint on the front of the pannier tanks in this shot.

Research is being carried out to ensure the right shade of brown is used, when the vast amount of preparation is complete and undercoating starts.

In this shot we see on the left, Steven Hopper the EHSI trainee at Locomotion.

Ear defenders are the order of the day, whilst needle gunning is carried out. I'm sure we'll see much more of this restoration as the job proceeds.

John also popped in to the North East Maritime Trust to see Rosie Power and Phil Smith.

Here's a shot of them both, under the whaleback that they have been working on for ages, which has now been offered up to the stern of the Henry Frederick Swan Lifeboat.

John on his travels, has also visited Ryan Auton at HMS Trincomalee in Hartlepool. These first couple of shots show his navigation skills, as he moves a work pontoon across the dock and loads it with wood for repairs on the ship.

Later Ryan had a simple repair to an access gangway to do. Here he removes the panel that covers the gap between the end of the gangway and the side of the ship.

After repairs and sanding down Ryan paints the panel.

When the paint dries he fixes the panel in place.

Joe gets on with cutting steel to make the legs of his forge.

After marking out and clamping, Joe drills the holes to mount the legs on the forge.

Later he bends so angle to make the frame of the smoke hood.

Then using the MIG welder he joins he welds the mitred joints of the the frame.

We leave Joe using a piece of cardboard to make a template, to mark out the sheet steel from which he will make the hood.

Moving south form Haltwhistle I have some shots from earlier in June, of EHSI trainee at the South Tynedale Railway, Zach Taylor. Readers will recall that last year's trainee, Andrew McIntyre repaired Hunslet mines locomotive 'Cumbria's' transmission. The Gardiner engine however, is beginning to show signs of engine wear and the railway has decided to strip it down to investigate. The shots that follow show Zach removing the inlet and exhaust manifolds and the cylinder heads. Eventually the Connecting rods and pistons will also be removed to check the state of the piston rings and cylinder bores.

Here we see Zach at the start of the job, the bonnet and cab have been removed and he's starting to remove the manifolds.

With the manifolding removed, its time to remove one of the two cylinder heads, which are in two sets of two, on this Gardiner 4 cylinder diesel engine.

Zach has now removed the cylinder heads and has started to strip down one of them on the bench.

Here's a shot show the manifold side of the head, you can just see the inlet and exhaust valves on the underside of the second cylinder head.

Our first story in this latest update is the restoration of a railway prison coach for the Maud Railway Museum in Aberdeenshire by Stanegate Restoration and Replicas.

The picture below shows the coach suspended from a crane, during recovery operations. Its been 'grounded' and thus the pitch pine structure, has rotten from the bottom upwards, leading to an unusual reconstruction process as the photos which follow will show.

Here's a little about the background to the project borrowed from Stanegate's website.

In 1886 the Admiralty commenced building the Harbour of Refuge at Peterhead, it was decided to quarry granite at Stirling Hill, using the labour of convicts who were housed in the prison built for the purpose.

The only state owned railway - at the time - was built to convey prisoners and stone.

The sole surviving convict van (one of four built in 1915) is to be restored as part of the "Rocks, Rogues, Rails and Refuge" project to explore this aspect of social and transport heritage.

Once completed the van, and associated displays, will become part of the Maud Railway Museum, in Aberdeenshire.

Here's a shot down the side of the coach with Jonathan Crowe, former EHSI trainee and now an employee at Stanegate, in the shot. He's preparing surviving good timber, for the fitting of new sections of timber, using scarfed joints.

Because the coach has rotted from the ground up, its been jacked up to its finished height with temporary internal and external bracing to keep the structure stable, whilst the missing timber is reinstated on the bottom of the 'legs', which make up the vertical element of the coach's structure.

Here's a close-up shot of how the ironwork looked at the start of the project, following de-rusting and painting the ironwork in the shot above, now looks much improved.

This is a close up of two of the 'legs' where new, scarf jointed Pitch Pine, has been fitted.

This is what scores of years standing on the ground, does to the coach's structure.

Here's a shot of Stanegate's EHSI trainee, Jamie Cowens, working with a belt sander, preparing for the fitting of a new scarf joint. The Pitch Pine structure that was exposed to the weather and didn't get 'its feet wet', has weathered very well.

A common problem on old coaches, is rusting ironwork, which over time expands and damages the wood in which it's mounted. This has happened with the Peterhead Railway coach.

The bars on the windows of the coach rusted so badly, that all the bars have had to be replaced. Here's a pile of new bars ready to be fitted.

Here's some of the new window bars dry fitted, to see how they fit in the window openings.

Looks like it would be difficult to escape!

Elsewhere in the workshop a client's steam engine canopy is in the workshop for repairs.

In this general shot of the workshop we see the end of N.E.R coach No.70 on the left, recently being worked on again and the Peterhead Prison Railway coach on the right, with the engine canopy in the foreground.

Outside is the underframe the Maud Railway Museum has acquired, on which to mount, the prison coach body.

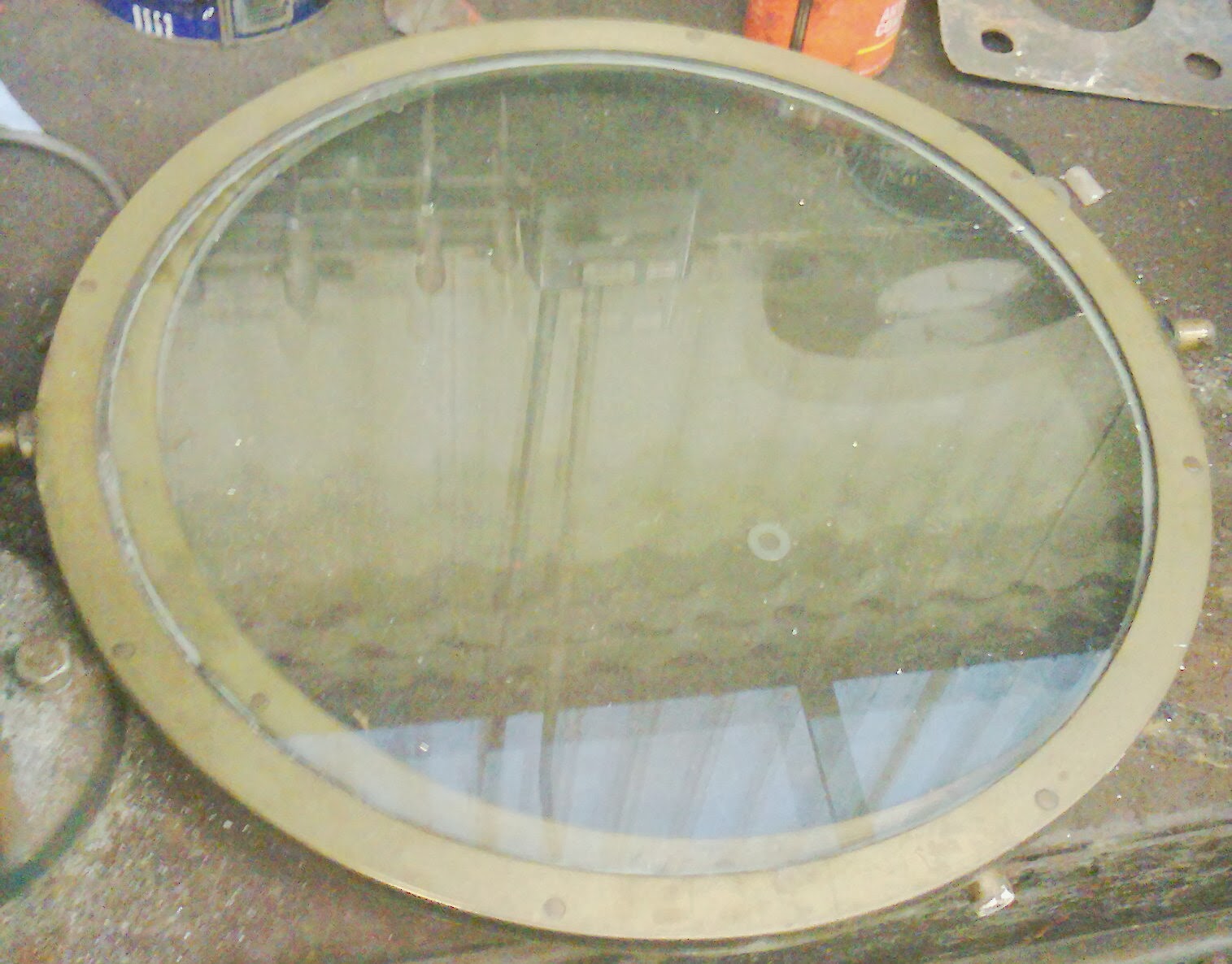

This 1960's built Fife motor sailing boat has been a long term project of Stanegate's Ian Yates.

Internally its been rebuilt with loving care as the shot below shows.

Now is the time for the outside to be caulked to seal the joints between the hull's planks.

Stanegate have assembled an impressive collection of caulking irons and mallets and this job, is next on the list for the boat. Here's a shot of the caulking gear, laid out ready for use.

Here's a shot of the boat ready for caulking.

Postings for the North East 27.05.2014

We last heard of Joe Power at Stephenson Railway Museum in North Shields when he was making some wrenches for wash out plugs. He's moved on to making components for gas lamps. in this shot we see him measuring a cast iron lamp standard to ensure the components he is making will fit when the lamps are assembled.

I visited EHSI trainee at South Tynedale Railway last week and caught up with what he's been up to in the North Pennines.

Zach work is focused mainly on engineering but he also spends some of his time with the track gang.

The STR have loaned 'Harrogate', a 1944 Peckett 0-6-0 from the Statfold Railway whilst the STR's locomotives are under repair. In this shot Zach is pointing out the regulator gland which he had just re-packed.

Here's a close up shot of the gland. Zach had to remove the regulator handle and then strip out the gland and repack it. The gland prevents live steam leaking when the regulator shaft turns to operate the regulator in the dome.

Postings for the North East 23.05.2014

At HMS Trincomalee Ryan Auton continues the maintenance work on the ship. The task this posting covers is more replacement of rotted timber. In this shot we see a rotted area of the ship's bulwark where the rotted area has been cut out ready for the fitting of a new piece of timber.

At the North East Maritime Trust in South Shields Rosie Power and Phil Smith have started the second year of a part time placement at the trust. Their most recent task has been to rebuilt the stern whaleback a distinctive curved wooden structure that is fitted on the stern and bow of the Henry Fredrick Swan. Rosie and Phil have taken on the challenging task of rebuilding the whaleback that has had to have many of its sharply curved planks replaced. This task has had many twists and turns and has also led to the rebuilding of the trust's steamer. The shot that follows is a close up of some of the sharply curved planks at the edge of the whaleback.

Postings for the North East 15.05.2014

I visited Joe power the EHSI trainee at the Stephenson Railway Museum the other day.

Joe has a woodworking background and at SRM is making the transition to working in metal.

One of his recent jobs was to hand file a square into a piece of steel which was then later welded to and old tool handle by a SRM volunteer to make a great tool for tightening up the wash out plugs on A No.5 locomotive. In this photo Joe is holding the wrenches he has made.

We last heard of Joe Power at Stephenson Railway Museum in North Shields when he was making some wrenches for wash out plugs. He's moved on to making components for gas lamps. in this shot we see him measuring a cast iron lamp standard to ensure the components he is making will fit when the lamps are assembled.

Later Joe cut out with tin snips a new sheet steel base for one of the lamp bodies.

He then used a vice to fold the edges of the sheet he had cut out.

Here's Joe with the finished item just making sure all the corners are correctly folded.

In the background is the Walschaerts valve gear of 0-6-0 Bagnall locomotive No.401 of 1953, who's boiler was sent to the North Norfolk Railway for a new firebox to be fitted.

Joe's next step is to test the fit of the new steel base in the lamp body.

Zach work is focused mainly on engineering but he also spends some of his time with the track gang.

The STR have loaned 'Harrogate', a 1944 Peckett 0-6-0 from the Statfold Railway whilst the STR's locomotives are under repair. In this shot Zach is pointing out the regulator gland which he had just re-packed.

Here's a close up shot of the gland. Zach had to remove the regulator handle and then strip out the gland and repack it. The gland prevents live steam leaking when the regulator shaft turns to operate the regulator in the dome.

This is s shot of the manifold on top of Harrogate's boiler. Zach also repacked the glands on three of the valves on the manifold, as part of the regular maintenance on the locomotive whilst its on loan to the railway.

An earlier job on Harrogate was to change the locomotive's fire bars which had become distorted. In this shot we see the old fire bars which Zach removed after first removing the ash pan from below the firebox.

Here's a shot of the inside of the firebox. In the bottom of the shot, the new fire bars which show no signs of distortion despite the railway's gradients being as steep as 1 in 56 in places.

As mentioned earlier Zach also works with the track gang. The shot below shows the point outside the signalbox at Alston station. The track gang dug out, dis-assembled and re-laid the point with new sleepers and ballast, and a very neat job they have made of it!

My colleague Stuart Hines also visited STR at the bank holiday weekend, you can read his posting at https://www.facebook.com/groups/146740965394085/?fref=ts

At HMS Trincomalee Ryan Auton continues the maintenance work on the ship. The task this posting covers is more replacement of rotted timber. In this shot we see a rotted area of the ship's bulwark where the rotted area has been cut out ready for the fitting of a new piece of timber.

In the workshop Ryan cuts a piece of new timber.

He then test fitted it after carefully cutting it to size.

Then he drills a recessed hole through which will be screwed a coach bolt and the hole then plugged with timber to create a smooth finish.

In this shot we see the replacement timber coach bolted in place.

In this shot the job is nearly done, sealant in place and the wooden plug just needs sawing off flush. Painting, of course, to follow.

Here's a shot of Rosie and Phil working on the upturned whaleback.

In this shot Rosie is preparing and area for a new piece of planking.

Here's a shot of Phil working on the inside of the whaleback.

Postings for the North East 15.05.2014

I visited Joe power the EHSI trainee at the Stephenson Railway Museum the other day.

Joe has a woodworking background and at SRM is making the transition to working in metal.

One of his recent jobs was to hand file a square into a piece of steel which was then later welded to and old tool handle by a SRM volunteer to make a great tool for tightening up the wash out plugs on A No.5 locomotive. In this photo Joe is holding the wrenches he has made.

To prove they work here's Joe showing how the wrench is used on A No.5

Joe's next job is to provide a finial for this ex BR signal post.

Postings for the North East 12.05.2014

I visited Locomotion today a got up to date with Steven Hopper who has been working on the former Southern Railway 'Queen Mary' bogie brake van and been assisting Steven Foxton with the GNR tender mentioned in earlier blogs.

On the GNR tender Steven Hopper assisted with a welded repair of the handbrake shaft guard.

In this shot he pints out the area that he helped to repair..

He also helped to fabricate this step from three separate pieces that were then welded together.

Steven also helped to fit the brake rods and hangers.

Here's another shot of the front of the tender which shows what a fine job has been made of a vehicle that was literally a wreck when it arrived at Shildon.

Steven is continuing to work on the Queen Mary brake van. Richard Pearson tells me that the vehicle is owned by the Bahamas Locomotive Society who have loaned it to the museum where it is used on the museum's demonstration line. The brake van is undergoing a repaint in the Shildon workshop. Here we see Steven rubbing down the paintwork prior to applying undercoat. With a vehicle this big that's a lot of surface preparation!

Repairs have also been made to the steel and wooden framed vehicle.

In this shot new wooden framing has been fitted under the bolted on steel panels that make up the sides of the van body.

Further along the same side, the lower edges of the panels have had new sections welded in place, where corrosion has taken hold.

Richard Pearson expects the van to be finished by the end of the month, so there's lots for Steven to be getting on with before the next project arrives, a GWR pannier tank to re-paint, this is expected on site on the 22nd of May.

Postings for the North East 28.04.2014

Last time we saw Joe Power at Stephenson Railway Museum he was sorting out a big pile of copper piping. He's still working on steam during John Stelling's recent visit he was getting on with a boiler wash out. In this shot we see all the wash out plugs and mud hole clamps laid out on the bench. All of these fittings have to be removed from the boiler to allow it to be washed out to remove the sludge that collects inside the steam spaces inside and at the bottom of the boiler. This sludge has to be removed as it reduces water circulation, a local build up of sludge may lead to localised overheating.

In this shot Joe is using a wire brush on a bench grinder to clean up one of wash out plugs.

Later Joe touches up the paint on one of the splashers from Locomotive A No.5

Last time we saw Joe Power at Stephenson Railway Museum he was sorting out a big pile of copper piping. He's still working on steam during John Stelling's recent visit he was getting on with a boiler wash out. In this shot we see all the wash out plugs and mud hole clamps laid out on the bench. All of these fittings have to be removed from the boiler to allow it to be washed out to remove the sludge that collects inside the steam spaces inside and at the bottom of the boiler. This sludge has to be removed as it reduces water circulation, a local build up of sludge may lead to localised overheating.

In this shot Joe is using a wire brush on a bench grinder to clean up one of wash out plugs.

Later Joe touches up the paint on one of the splashers from Locomotive A No.5

Lets meet some more of our new year 4 EHSI North Eastern trainees. Steven Hopper's placement is a Locomotion in Shildon.

He's been helping another Steven, Steven Foxton, the year 2 EHSI trainee at Locomotion, now working at the museum on a contract, to restore a a correct period, Great Northern Railway tender, which on completion, will be matched with GNR single No.1, which is on display at Shildon.

In the sequence of photos that follow we see Steven repairing a sheet steel guard that covers the vertical handbrake shaft on the tender. This was also Steven's first opportunity to develop some welding skills.

After cutting out an area of corrosion Steven shapes a steel patch on the anvil. which he will weld in place to make a repair to the brake shaft guard.

Steven prepares the area for welding

After welding Steven starts to dress the weld.

Later after cleaning he applies a coat of primer.

Here we see Steven with some of the other components for the tender which he is preparing for painting with undercoat and topcoats.

While were at Locomotion, lets look at progress on the GNR tender the our former EHSI trainee Steven Foxton is restoring. Here's the tender early in its restoration in August 2008.

Here's a recent shot of the tender in the Locomotion workshop. I'm sure readers will agree its a remarkable transformation by Steven and his volunteer helpers. I understand, its due to be reunited with GNR No.1 at Locomotion's Spring Steam Gala, this coming weekend.

Moving across to the Tyne Valley Stanegate EHSI trainee Jamie Cowens is working on Stanegate's latest project a very unusual prison coach from the Peterhead Prison Railway.

Read more about its history at http://www.friendsofmaud.org.uk/index_files/Page513.htm

go to the Rocks, Rogues, Rails and Refuge section of the page above.

In this shot Jamie works on the coach's framework with a chisel.

Nearby Luke Bell, last year's EHSI trainee, now employed at Stanegate uses a hole saw to cut out areas of the pitch pine framework where rusty bots have expanded and cracked the wooden structure. When all of the damaged areas of wood have been removed the damaged areas will be repaired as part of the restoration process.

Postings for the North East 03.04.2014

Our year 4 trainees have all settled in to their traineeships so lets catch up with what they've been doing.

First up is Michael McCann who is this year's EHSI trainee at Tanfield Railway.

There's quite a lot going on at Tanfield the continuing rebuild of 'Horden' including the re-tyring of driving wheels + the rebuild of the cab, the removal of 'Twizell's boiler and the locomotives re-assembly. Add in the repair of an excavator bucket, the drilling of a tubeplate and a buffer beam and you can see Michael has had quite a bit of variety in the first two months of his traineeship.

Tanfield Railway often tackle some of the more difficult tasks in locomotive repair and restoration, an example is the re-tyring of the Horden's driving wheels.

Having sourced and machined new tyres for the locomotive it was time to fit the tyres.

It was some years since the job was last done, so the work started by working with Brian High and John Lennox on making a new circular gas burner. The burner would be used to heat the tyre so that it could be shrunk on to the wheel centre.

Here we see Michael and Brian working on the fabricating the burner.

Here's a shot of the bucket which still needs some more work to complete the task.

Here's A5 running for the first time in nine years!

Latest news postings for EHSI North East

First up is Michael McCann who is this year's EHSI trainee at Tanfield Railway.

There's quite a lot going on at Tanfield the continuing rebuild of 'Horden' including the re-tyring of driving wheels + the rebuild of the cab, the removal of 'Twizell's boiler and the locomotives re-assembly. Add in the repair of an excavator bucket, the drilling of a tubeplate and a buffer beam and you can see Michael has had quite a bit of variety in the first two months of his traineeship.

Tanfield Railway often tackle some of the more difficult tasks in locomotive repair and restoration, an example is the re-tyring of the Horden's driving wheels.

Having sourced and machined new tyres for the locomotive it was time to fit the tyres.

It was some years since the job was last done, so the work started by working with Brian High and John Lennox on making a new circular gas burner. The burner would be used to heat the tyre so that it could be shrunk on to the wheel centre.

Here we see Michael and Brian working on the fabricating the burner.

In this shot John Lennox holds the burner whilst Michael finished of the final bit of welding.

Notice the burner is now fitted with its control valves.

Having made the burner it was time to fit the tyres, Some of the shots that follow have been 'borrowed' from Derek Smith's excellent Tanfield Railway Blog. First job was to put the newly machined tyre level on a steel plate ready for heating. The gas burner rests against No. 49's buffer beam.

Then some careful cleaning of the wheel and the tyre.

Then it was time to 'cook on gas', heating the tyre to expand it sufficiently, to allow the wheel to fit inside the tyre and shrink to a tight fit after cooling.

The Tanfield team made a gauge with which they checked the tyre to make sure it had sufficiently expanded, when the tyre was the right size the axle was lowered into the tyre with the Railway's Telehandler. Michael and Brian check alignment during this tricky manoeuvre.

Both tyres were fitted to the axle and after cooling we see the finished job in the workshop.

Work has continued on the repairs to Horden's cab. In this shot we see Michael at work on the cab platework.

The rear of the cab has been replaced, but notice the gouges near the roof on the side of the cab. It has been decided to retain some of Horden's damaged cab platework, to show some the 'battle scars' it suffered, during its colourful life at Horden and Shotton collieries.

The Tanfield team later assembled the cab and Michael was involved in it's trial fitting to ensure a good and square fit. The cab will have to be removed again when the time comes to re-fit the boiler.

During its time at Shotton Horden was involved in a collision, in which it suffered damage to its front buffer beam. Michael has worked on drilling the mounting holes in a new buffer beam, using a magnetic drill.

Another piece of precision drilling was the new boiler front tubeplate, Michael helped with the careful marking out and drilling of the tubeplate. Here's the tubeplate almost finished.

One of the railway's excavator buckets had worn very thin.

Michael gets to work repairing the bucket's platework.

Michael has also helped out on Twizell's rebuilding, here he was working again with Brian, on adjusting the locomotive's rearmost axle's volute springs. The Locomotive's repaired boiler waits in the background to be fitted to the chassis.

Although it harks back to last year here's a couple of shots of Stephenson Railway Museum's Locomotive No. A5 the only operational Long boilered locomotive in the country. It last operated under steam in 2005. Last year's EHSI trainee Tom Naisbitt returned specially to the museum to assist with its steam test.

Here's Tom preparing for the steam test.

On the footplate during the test

We now move on to HMS Trincomalee and EHSI trainee Ryan Auton in Hartlepool.

The ships bulwarks, the wall of wood that surrounds the top deck, is fitted with a decorative half round moulding. Ryan has been working on removing some of these mouldings that have suffered from internal rotting.

HMS Trincomalee was built in Bombay from Indian teak due to the shortage of oak which even by 1817 was in short supply. When the ship was restored, teak was no longer commercially available, so a West African hardwood called Bilinga, known as Opepe in the UK, was used to restore the ship. This wood, unlike teak which is oily, is a 'dry wood' which means it can absorb moisture and lead to fungal rot.

Here's a close up of the moulding before work began, outwardly everything looks fine.

However on the underside are some worrying signs of rot.

Ryan gets to work cutting out the rot and soon the true extent of the rot is revealed.

We'll keep you posted on Ryan's progress with the repairs to the mouldings on the bulwarks, in due course.

Latest news postings for EHSI North East

Postings for the North East Thursday 13.03.2014

North Staffordshire Railway 3rd class coach is now mounted on its chassis and has been dispatched to the owners, the North Staffordshire Railway Rolling Stock Trust at the Foxfield Railway.

Here's a shot showing it in use as a garden shed.

The grounded body arrived at the railway in 1976, here it is on arrival.

The railway carried out a partial restoration.

The coach was then sent to Stanegate for a full restoration, now just completed.

Here's the finished coach on its underframe, outside Stanegate's workshop in Haltwhistle.

Later on the low loader ready to go to Staffordshire.

The coach shown on the Haltwhistle by-pass starting its Journey to Staffordshire.

Finally back home at the Foxfield Railway, 137 years after its construction in the NSR workshops beside the Trent and Mersey Canal in Stoke on Trent.

Postings for the North East Monday 03.03.2014

A visit to Stanegate Restoration during the induction week enabled us to see the progress that is North Staffordshire Railway coach No.6. This coach is nearing completion now and since these shots we taken has had its roof sticks, roof boards fitted and canvas roof covering fitted.

In this earlier shot we see the a painted compartment, again since then seats have been fitted and the cream boarding has been given a scumbled finish to simulate wood grain.

Here we see one of the ends of the coach now with one of the top coats applied.

Moving on to Tanfield Railway, last week I caught up with Richard Snowdon before he left the project to take up a new job and new Tanfield trainee, Michael McCann. Richard has taken up a new job in a car body repair shop. Both were working on the new back to the cab, of 1904 built, Andrew Barclay, 0-6-0 saddle tank, 'Horden'.

In this shot we see the upper portion of the cab on the workshop floor. Richard and Michael were cutting new steel plate to replace the missing rear portion of the cab, that is being replaced due to advanced corrosion.

Here's Richard cutting the new plate for the back of the cab.

Later it was MIchael's turn with the plasma cutter.

Another task Michael is working on is the drilling of the new front boiler tube plate for 'Horden's'

boiler. In this shot the old tube plate has been temporarily welded to the new tube plate. It is being used as a template to drill the pilot holes for the fire tubes, which will eventually be inserted between the smokebox and firebox tube plates.

As the cutting out of the plate for the back of the cab was nearing completion Michael and Richard worked together on the job.

In this next shot we can see he's already been quite busy cleaning the various lengths of pipework and boiler fittings from the steam roller.

Tom's replacement at SRM is Joe Power here we see Joe cleaning up some steam pipework form a steam roller which SRM has in storage. Joe was explaining to me what he was doing.

Here's a final Shot of Tom Naisbitt days before leaving the project at the end of February. Here he's painting the boiler cladding which sustained some scratches to the paintwork when it was being refitted to the locomotive. He's moved on to pastures new in Leeds, we wish him well for the future.

Postings for the North East Saturday 16.02.2014

Later in the day we visited William Lane foundry, where through unusually good timing, we arrived just when molten metal was about to be poured. Here we see EHSI trainees watching the casting process.

In this shot MD Edward Bilcliffe explains the moulding process.

As posted on our Facebook page the shot below is of 7 of our 2014/15 intake of trainees at the North East Maritime Trust boatyard in South Shields

Left to right the trainees and their placements are:-

Steven Hooper - LocomotionJamie Godwin - Adam Dalgleish Engineering, boilermakers Stockton

Ryan Auton - HMS Trincomalee

Michael McCann - Tanfield Railway

Joe Power - Stephenson Railway Museum

Zach Taylor - South Tyndale Railway

Joel Vernon and Ryann Hodgson have now been recruited for William Lane foundry Middlesbrough.

Postings for the North East Saturday 25.01.2014

I recently visited Tom Naisbitt again at Stephenson Railway Museum to see how they are getting on with the re-assembly of 1883, Kitson Long-boiler locomotive, Consett Iron Company 'A No.5'. Following a successful hydraulic test, the boiler lagging and cladding has been replaced, and just before my visit the two pannier tanks had been re-fitted to the the locomotive.

In this shot Tom points out the fixing bolts that hold the tank in place.

The two shots that follow show the excellent progress that SRM are making with the locomotive's re-assembly.

Looking down the other side we see the dome cover yet to be fitted and in the red casting in the foreground is one of the locomotive's steam injectors.

Here's a close up of the mounting for the Ramsbottom steam safety valve and the dome, whose bolted cover had just been re-fitted by Tom.

Inside the cab some of the boiler fittings are in place, with the remainder yet to be fitted.